Tested Vehicle Restraint Systems are mandated for use across the UK as they contain and redirect errant vehicles, preventing them from impacting vehicles in the adjacent carriageway. As outlined in CD377 (previously TD19-06), a typical compliant layout will account for a terminal or anchorage, a connection or transition into the relevant barrier and then the suitable length of need for the barrier to protect road users from the hazard identified.

To determine the performance rating of each Vehicle Restraint System, they must be tested and approved to one of the following standards: EN 1317 (predominately UK and Europe), NCHRP 350 (USA) or MASH (predominately USA); MASH only should be used moving forward but this is dependent on each State. Other countries may adopt the fore mentioned test standards to meet their requirements. Hill & Smith have a variety of tested vehicle restraint systems that are compliant to the latest VRS standards; the classification and approval of these safety barriers is regulated by an independent testing facility and external over-seeing body, along with annual audits.

XtratechWhy not arrange a Lunch and Learn with our lead Engineers to find out more about Vehicle Restraint Systems? Find out about the latest innovations, new assessment criteria, CD377, connectivity between existing and new VRS and much more! Our Lunch and Learn sessions can be held remotely or traditionally in a covid-safe environment. Following the learn and learn programme, our design engineers and commercial team will be able to assist you on future designs.

Vehicle restraint systems must be tested to EN 1317 and approved by an independent body before being considered for any highways installation. EN 1317 is a public document authorised and influenced by European industry working groups to ensure the controls within the test standard produce safe and complaint road restraint systems. Different containment classes are used to accommodate the various vehicle types present on our UK road network. As an experienced manufacturer, we have developed a range of Flexbeam highway safety barriers to both normal and high containment levels, with working widths from W1 to W8, to ensure all vehicles on our road network are appropriately contained and safely redirected. When testing a road safety barrier to EN 1317, the working width, the dynamic deflection, the impact severity and the vehicle intrusion (high containment only) are all measured and recorded in a final report.

EN 1317 is used to qualify the performance of bridge parapets and transitions. A tested transition allows for a seamless connection between the vehicle restraint system and the parapet thus preventing breaching or pocketing upon impact. Hill & Smith are the only company in the UK to have a range of tested and approved transitions, that integrate with Varley & Gulliver bridge parapets. These transitions have been used on some of the largest UK road developments, including the Aberdeen Bypass and the A14.

The working width is measured during an EN 1317 impact test to measure the deflection of the vehicle once it has impacted the barrier. The measurements are referenced from W1 to W8. A working width classification will be determined following a RRRAP assessment.

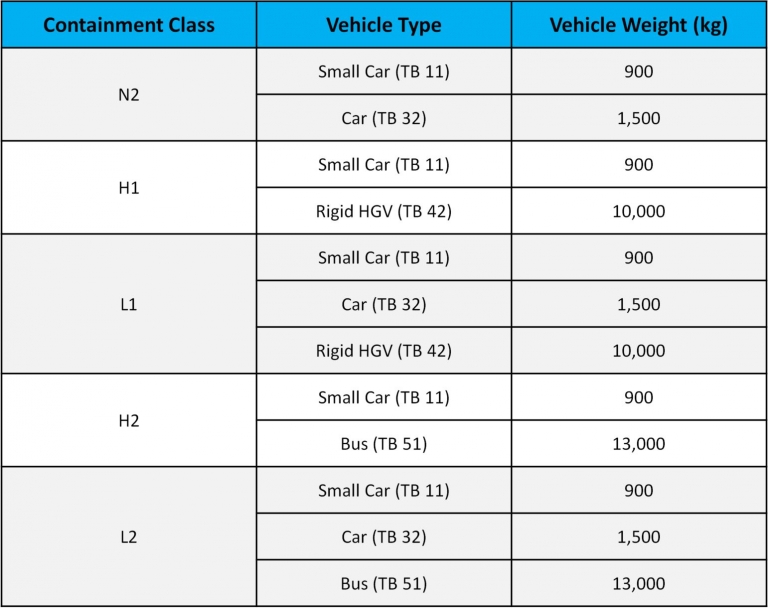

Containment classes are differentiated between vehicle types and weights.

Vehicle Intrusion measures the vehicles ‘lean’ from the furthest point of deflection to the furthest point of which the vehicle leans thereafter.

Hill & Smith was the first barrier manufacturer in the UK to create a portal that publicly made installation drawings, installation manuals and declarations of performance readily available to download. This portal is known to industry professionals as the XTRATECH.

XtratechNCHRP 350 is the American Standard developed and authorised by AASHTO which outlines the recommended procedures for the safety performance evaluation of highway features, including vehicle restraint systems. The Brifen is a wire rope (cable barrier) safety barrier system used around the world and is both TL3 (normal containment) and TL4 (high containment) compliant. NCHRP 350 permits the testing of wire rope safety barriers as they offer different performance benefits to a guardrail VRS. The containment level (TL3 or TL4) of the vehicle is the only variable recorded in a NCHRP 350 safety barrier test. As this is an American standard, the application of an NCHRP 350 approved safety barrier is different so the testing parameters are much looser in comparison to EN 1317.

MASH has been developed to supersede NCHRP 350. Vehicle restraint systems currently approved to NCHRP 350 are still valid. However, countries and states that comply with the American standard should now use MASH compliant systems wherever possible. This new standard has been updated to consider additional impact angles and vehicles types that are now much more common. The Brifen VRS is approved to both NCHRP 350 and MASH (TL3). It is the first wire rope safety barrier to be completely MASH complaint.

MASH compliant vehicle restraint systems are now mandated for future use on highways across all of Australia and New Zealand. As the Brifen VRS is the only totally MASH TL3 complaint wire rope system in the world, it has been successfully approved by ASBAP, the Austroads Safety Barrier Assessment Panel.

Our Products